Home

About us

Albert Hodel GmbH is a manufacturer of special components for the laundry industry with an export share of more than 90%.

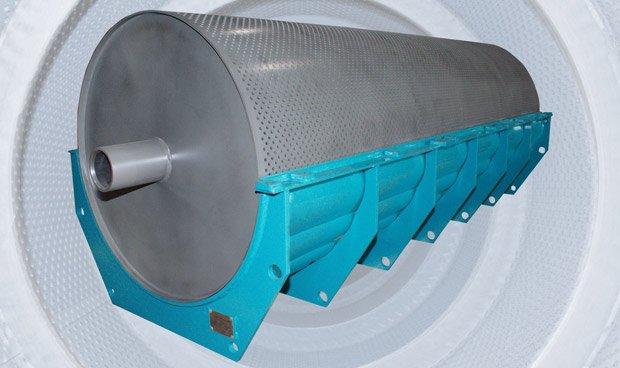

Our key competence is the manufacturing of chests, rollers and gap pieces for the use in industrial ironers.

We manufacture in this field diameters up to 2000 mm and lengths up to 4200 mm.

Additionally, we have specialized in the production of highly effective heat exchangers for biogas plants, in custom-built products for customers in the field of mechanical engineering, special constructions in different industries.

Currently, our team consists of 35 employees.

Our production facilities of 4,000 square meters are built on 6,000 square meters premises.

Our promises to you:

More than 3 decades of experience

In the last 3 decades, HODEL has built more than 25,000 chests and rollers for the world´s leading manufacturers of industrial ironers. This enormeous number speaks for itself . The basis for long-term trusting cooperations with our clients is a high degree of understanding and responsiveness of individual customer requirements.

Our customers as well as their end customers benefit from these advantages.

Product life time for decades

Operating durations of our chests and rollers of 20-30 years are definitely no exception, but the rule.

This is only possible thanks to the many years of experience of our staff and an extensive knowledge of the product requirements arising during the life cycle.

Maximum efficiency in all fields of activitiy is our standard

In 2012 HODEL started - in addition to its core business - to produce so called double-helix heat exchangers for the thermal processing of flowable biomass, used in biogas plants all over the world.

Plant operators appreciate this special component as it significantly increases the efficiency and availability of their systems.

Hommeswiese 75, 57258 Freudenberg, Germany

|

49 2734 495270